One size doesn’t fit all when it comes to building a supply chain. Each company needs to consider its goals and operation management strategy when designing a supply chain. Companies also need to account for the cultural aspects of their suppliers because communication is key to any successful relationship.

Language barriers and the meaning of different phrases can vary across cultures, leading to misunderstandings in directions. Management of both a company and its suppliers must work toward the same goals and objectives, and both must understand what is expected.

It’s important to understand the relationship between a product or service and a company’s business strategy and point out how this relationship influences the supply chain.

Define product demand

Before developing a supply chain, a company needs to understand the nature of the demand for its products. The supply chain needs for a product with stable demand (a well-established or mature product) are different from those for a product with less predictable demand (an innovative product).

Functional products typically have a demand stream that’s well-known and predictable. For your local grocery store, these products include staple food products such as breakfast cereals and milk. Functional products typically have a long product life cycle, meaning that the products don’t change dramatically over time. Functional products also often have low profit margins because they’re considered a commodity, and many substitutions (generic products) are available.

Innovative products, on the other hand, are new and often revolutionary products that have a demand stream that’s not well-known and unpredictable. Innovative products are characterized by variable demand, shorter product life cycles, and higher profit margins. Examples of innovative products include most consumer electronics, computer games, and fashion apparel.

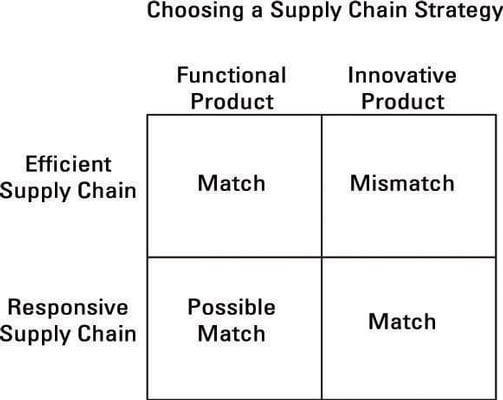

Choose the right supply chain strategy

Depending on the type of product that a business sells, supply chain development may take on one of two basic looks. Here are the primary supply chain categories:

Efficient supply chain: Usually a make-to-stock (MTS) producer that draws from a large finished goods inventory. Functional products usually benefit from an efficient supply chain because demand for these products is stable, allowing the company to maintain inventory with minimal risk of overstocking or being left with inventory that doesn’t sell.

Responsive supply chain: Usually produces make-to-order (MTO) products. With their high demand variability, innovative products benefit from responsive supply chains that can deliver products quickly without maintaining a finished goods inventory.

You can implement a responsive supply chain for functional products under certain circumstances. Because responsive supply chain companies don’t maintain inventory, they must be able to quickly produce the products needed. These companies must embrace lean principles.

A major supply chain mismatch is an innovative product trying to operate in an efficient supply chain, although many companies find themselves in this situation. This pairing is especially common in markets where companies find that the life cycle of their products are rapidly decreasing, such as mobile phones. (How many versions of the iPhone exist?)

Efficient supply chains tend not to serve innovative products well because they benefit from long production runs that result in the buildup of inventory. If a product’s demand is highly variable and unknown, this inventory presents a sizable risk.

When a firm sells both functional and innovative products, designing a successful supply chain gets tougher. In this case, the firm may have different supply chains for different product offerings.

Just be aware that not all the vendors in a firm’s supply chain need to operate exclusively as an efficient or responsive supplier. For example, a consumer electronics firm may require that its Tier 1 suppliers be responsive to accommodate the variability in demand.

Because a particular supplier can provide a certain component to more than one firm, the supplier may operate according to the efficient approach because its demand variability can be reduced across multiple customers.