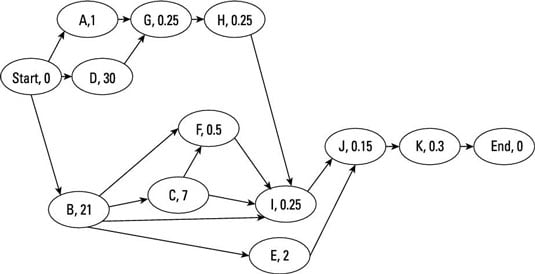

Figuring out how much time you need for various activities and operations is difficult. For this, try a critical path diagram. A critical path diagram identifies which activities need to be completed before other activities begin. These activities are also called predecessors and must be carried out before the subsequent dependent activities can begin.

The critical path diagram is an important reference for determining which operations can happen at the same time and which can be scheduled independently. It also tells you which activities can be delayed without delaying the entire project — and which ones can’t.

Activities that can’t be delayed without jeopardizing the project schedule overall are called critical path activities; their sequence is called the critical path. The critical path determines the shortest possible timing of the project. A project always has a critical path. It’s neither good nor bad. What’s important is that you identify it correctly.

Consider a volunteer project to build an outdoor sitting area with several benches. Sometimes, you may see activities labeled with letter identifiers instead of numbers.

| Label | Tasks | Predecessors | Days |

|---|---|---|---|

| A | Select site with client | None | 1 |

| B | Recruit volunteers | None | 21 |

| C | Get landscaping tools | B | 7 |

| D | Secure donations | None | 30 |

| E | Build park benches | B | 2 |

| F | Clear sitting area of trees and debris | B, C | 0.5 |

| G | Buy materials | A, D | 0.25 |

| H | Transport materials to work site | G | 0.25 |

| I | Landscape sitting area with crushed limestone | B, C, F, H | 0.25 |

| J | Situate benches in sitting area | E, I | 0.15 |

| K | Clean up | J | 0.3 |

To begin the process of determining timing requirements for this project, look for activities without predecessors — activities that can begin without any other activity being completed beforehand. Activities A, B, and D qualify; they can start before any other activities are complete.

Next, identify activities that do have predecessors. In the outdoor sitting area project, volunteers supply the landscaping tools, so activity C is dependent on activity B. Activity E is also dependent on activity B for the labor. Activity G needs to be preceded by both Activity A and D. Activity I requires completion of activities B, C, F, and H.

If you have any doubt about whether an activity is a predecessor, go ahead and list it as one. Adding a predecessor unnecessarily won’t affect your timing calculations, but missing a necessary dependence will almost always mess up your calculations.

Now you’re ready to draw a critical path diagram. Follow these steps to create a diagram for the outdoor sitting area project:

Put each activity with no predecessors in a circle.

Arrange these circles in a vertical line if you can, although this isn’t critical. These activities are A, B, and D.

If you don’t have enough space in the circles (called nodes) to list the title of an activity, use its label.

Label each activity with an estimated duration inside the circle.

Time is presented in units of days.

Draw a new circle to the left of the circles showing activities with no predecessors.

Label it Start, with a duration of 0.

Connect the start node to the initial activities with an arrow.

The direction of the arrows indicates which activities are predecessors and which are successors.

Then, working sequentially, find the activities that follow the existing activity circles and add them to the diagram, placing them to the right of their predecessor(s).

Continue this process until no more activities remain.

Add a final node and label it End, with a duration of 0.

Connect all the activities with no successors to the End activity. You now have a complete critical path diagram, also sometimes called a critical path method (or CPM) diagram.